By Annalloyd Thomason, Vice President/General Manager, NGVi

N

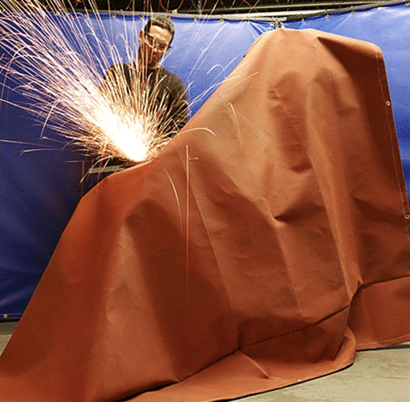

The first and most basic safety procedure to implement for welding on or around a CNG or LNG vehicle is to protect all the fuel system components with a welding blanket or other fire retardant device. This includes not only CNG cylinders or LNG tanks, but also any exposed components including stainless steel tubing and fittings, regulators, etc. This is necessary because if welding slag comes into contact with NGV fuel system components, it can cause damage that may compromise the safety of the fuel system.

In addition to the basic precautions described above, other safety measures may be advisable, depending on the circumstances and the level of risk protection your company chooses. These may include:

- The use of a Hot Work Permit process in advance of the welding procedure that is monitored and signed off on by a management representative.

- Ensuring that available sprinklers, hose streams, and fire extinguishers are in service and operable.

- Ensuring that the hot work equipment is in good repair.

- Removing any flammable liquids, dust, lint or oil deposits from the welding area.

- Ensuring floors are swept and clean.

- Ensuring that any combustible floors are wet down, covered with damp sand or fire-resistant sheets.

- Remove other combustibles where possible. Otherwise protect with fire-resistant tarpaulins or metal shields.

- The use of fire-resistant tarpaulins suspended beneath the hot work area.

- Institute a fire watch/hot work monitoring system where

- Fire watch is provided during and for 30 minutes after work.

- Monitor hot work area for 30 minutes after job is completed.

- Other precautions that may be taken could include

- Protect the welding area with separate smoke, heat, or flame detection.

- Use appropriate lockout/tagout procedure.

Finally, when the welding or hot work is complete, the CNG/LNG fuel system should be inspected for leaks before returning the vehicle to service.

This is the fifth and final article in the series “Upgrading Your Vehicle Maintenance and Repair Facility for NGVs”. If you have questions, or would like to speak with one of our experts about Vehicle Maintenance Facilities, call us at 800-510-6484 or email our Customer Solutions Manager Sabrina Dodd at sdodd@ngvi.com.