Transit agencies are one of the most active adopters of natural gas vehicles, due to the favorable economics and unparalleled environmental benefits of natural gas. There are nearly 20,000 natural gas buses on U.S. roads, and about 35% of new transit buses are powered by CNG.

Transit agencies are one of the most active adopters of natural gas vehicles, due to the favorable economics and unparalleled environmental benefits of natural gas. There are nearly 20,000 natural gas buses on U.S. roads, and about 35% of new transit buses are powered by CNG.

Since transit buses routinely operate in more densely populated areas, transporting millions of citizens across the nation daily, safety must be a major focus on transit agencies’ minds. Although CNG is an inherently safe fuel, it is stored onboard buses at very high pressures, so it requires special safety measures and handling procedures. There are four essential best practices that every transit provider operating natural gas-powered vehicles should implement to help ensure public safety.

1. Adopt and use industry-recommended inspection intervals

CNG fuel system inspections must be conducted frequently enough to detect potential safety issues. While inspection of all CNG cylinders is required by Federal Motor Vehicle Safety Standard (FMVSS) 304 every three years or 36,000 miles, whichever comes first, NGV industry best practices were amended in 2008 to include inspection of the entire high-pressure portion of the fuel system.

In order to identify any unsafe conditions before they become a serious problem, there are four different inspection intervals that NGV fleets, including transit agencies and other bus transportation companies, should adopt as official policy.

These intervals include:

- Pre-Service Inspection

- Driver Pre-and Post-Trip Inspections

- General Visual Inspection; and

- Detailed Visual Inspection

The Pre-Service Inspection is a detailed visual inspection of all high-pressure fuel system components performed by a certified or qualified CNG fuel system inspector. This inspection should be performed independent of the vehicle manufacturer, or dealer, upon delivery of a new CNG vehicle.

This inspection has multiple roles. It ensures that the vehicle meets all code requirements, identifies any problems or concerns with the CNG fuel system installation, and gives an important baseline inspection, which the results of all future inspections can be compared to.

Driver Pre-and Post-Trip Inspections are required by the Federal Motor Vehicle Carrier Safety Administration (FMCSA). These inspections should be conducted daily by bus drivers and should involve an inspection of any easily accessible and visible CNG fuel system components, especially to the cylinder shields. If any accidental damage is found, the damage should be reported and the vehicle should not be driven.

The General Visual Inspection is a basic inspection of all visible elements of the CNG fuel system, including cylinder shields, which should be performed regularly by trained technicians as part of a vehicle’s routine maintenance schedule. Technicians should look for any signs of damage to all visible fuel system components and mounting systems. If component damage is observed, it should be repaired or replaced before the vehicle is driven again. If shield damage is found, the vehicle must undergo a detailed visual inspection, as there may be damage to the cylinder.

The General Visual Inspection is a basic inspection of all visible elements of the CNG fuel system, including cylinder shields, which should be performed regularly by trained technicians as part of a vehicle’s routine maintenance schedule. Technicians should look for any signs of damage to all visible fuel system components and mounting systems. If component damage is observed, it should be repaired or replaced before the vehicle is driven again. If shield damage is found, the vehicle must undergo a detailed visual inspection, as there may be damage to the cylinder.

The Detailed Visual Inspection is the most thorough inspection, which covers the entire high-pressure fuel system, including cylinders, and must be conducted by a qualified or certified CNG fuel system inspector. This inspection is required by DOT FMVSS 304 and requires that inspections of cylinders take place every three years or 36,000 miles, whichever comes first, and after any accident or fire. At the same interval, industry best practice calls for an inspection of the entire high-pressure CNG fuel system.

2. Implement Standard Operating Procedures (SOPs) for all possible scenarios that may occur during driving, maintenance and repair of CNG buses

To prevent hazardous conditions, and to know how to respond quickly to emergency situations, transits should create procedures for all possible occurrences and develop plans on how to deal with each one.

Some important SOPs include instructions and safety measures for CNG bus drivers in case of an accident or fire. Questions covered by these SOPs may include:

- Under what conditions are passengers evacuated from the bus in case of an accident?

- How should the driver be trained to assist First Responders if necessary?

- What are the conditions that require towing vs. driving the bus back?

- In case of an accident, when and where would the required Detailed Visual Inspection take place?

Another set of SOPs that the transit agency should develop are for maintenance and repair. These policies may include:

- A standard policy for bringing buses into the maintenance facility

- Procedures and conditions for depressurizing or defueling CNG cylinders

- Safety protocols for welding or hot work on CNG buses

- A procedure to follow in the event the methane detection system inside the maintenance facility system is activated

Finally, the third group of SOPs covers essential procedures for CNG fuel system inspections. These include:

Finally, the third group of SOPs covers essential procedures for CNG fuel system inspections. These include:

- A list of tools used and the specifications required to perform inspections

- The requirements for removing cylinder shields

- The requirements and necessary documents for inspection record keeping

- Procedures to be used when cylinder damage is assessed

- Measures for defueling and isolating cylinders when Level 2 or 3 cylinder damage is found

- Recommended actions for isolating vs. removing Level 3 damaged cylinders

- Documented procedures for destroying and disposing of expired or Level 3 damaged cylinders

3. Require an appropriate level of CNG training for each employee

Comprehensive safety training is one of the most frequently overlooked elements by many CNG fleets, including transits. Fleets often opt only for specific product familiarization training provided by the manufacturer. While familiarization with the product is needed for technicians who will operate them, a comprehensive safety training is essential to ensure technicians have the skills and knowledge necessary to perform their jobs safely and accurately.

Every employee who works on or around CNG buses should have a level of training that corresponds to their job responsibilities.

Drivers need to be familiar with the properties of natural gas and know how to use the safety features of the vehicle. They need to know how to detect signs of damage, leakage, or wear on the visible elements of the fuel system, and what safety protocols to follow in case of an emergency or fire. When needed, they should also be able to provide basic guidance to first responder personnel who may not be familiar with CNG or CNG-powered vehicles.

Every technician working on or around CNG vehicles needs at least Level 1 safety training, which will teach them the unique properties of the fuel, as well as the principles of working around compressed gas. They should become familiar with all of the CNG fuel system components, their functions, and all related safety practices. In addition to technicians, maintenance management and any employees doing work on or around CNG vehicles should receive Level 1 safety training.

Every technician working on or around CNG vehicles needs at least Level 1 safety training, which will teach them the unique properties of the fuel, as well as the principles of working around compressed gas. They should become familiar with all of the CNG fuel system components, their functions, and all related safety practices. In addition to technicians, maintenance management and any employees doing work on or around CNG vehicles should receive Level 1 safety training.

More advanced technicians are usually assigned the task of conducting the required CNG fuel system inspections. CNG fuel system inspectors must not only have the Level 1 training, but they must be familiar with fuel system installation code requirements and standards, and be trained to identify and assess damaged components, including various damage levels to CNG cylinders.

Level 3 training prepares technicians who will be performing diagnostics and repair to either the CNG fuel system or the engine. In addition to the Level 1 training, these technicians need training that teaches them about the unique components of heavy-duty natural gas fuel systems and engines, how to distinguish between a fuel problem, a fuel system problem and an engine problem, and how to diagnose problems that do not set codes in the controls.

Level 3 training prepares technicians who will be performing diagnostics and repair to either the CNG fuel system or the engine. In addition to the Level 1 training, these technicians need training that teaches them about the unique components of heavy-duty natural gas fuel systems and engines, how to distinguish between a fuel problem, a fuel system problem and an engine problem, and how to diagnose problems that do not set codes in the controls.

Appropriate safety training should be provided to all staff, including periodic training for new employees, as well as refresher training for existing employees. Refresher training should be provided annually to ensure key principles and practices are reinforced for technicians’ daily activities and to remain current on any code, standards, or technology updates.

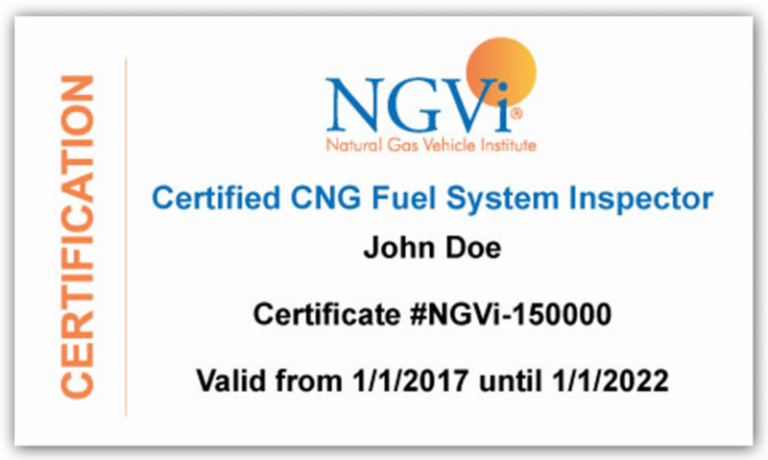

4. Require certification for all CNG fuel system inspectors

While there is no national requirement that CNG fuel system inspectors be certified, certification is the NGV industry’s recommended practice. This independent assessment measurably demonstrates technician knowledge and skills required to perform CNG fuel system inspections according to all codes, standards and industry best practices. These important skills include the ability to:

Understand the function of each CNG fuel system component and their inspection requirements, and to identify damage or disrepair.

Understand the function of each CNG fuel system component and their inspection requirements, and to identify damage or disrepair.- Correctly distinguish between the four types of CNG cylinders, assess their damage types and levels and determine whether this damage is repairable or if the cylinder must be condemned.

- Identify the manufacturing, installation and inspection standards for CNG fuel systems, which may vary from model year to model year, depending on the codes in force at the time.

- Correctly apply CNG installation and inspection standards to perform CNG fuel system inspections.

- Determine the final disposition of CNG cylinders after a CNG fuel system inspection.

- Properly defuel and dispose of condemned CNG cylinders.

To prevent incidents and demonstrate that the transit agency has done everything reasonable to protect its employees, their customers and the general public, certification is highly recommended.

Working on or around NGVs requires special awareness of safety procedures that are unique to these vehicles. It is imperative that transits — one of the largest adopters of CNG who routinely operate in densely populated urban and suburban residential areas — be proactive in mitigating risk by implementing safety practices and procedures that protect their employees, passengers, and the general public. By implementing all four best practices described in this article, safety-leaders in regional transit systems can be sure that the gold standard for safety in their CNG fleet is achieved.

|

NGVi’s offers ASE-accredited training courses that cover the full spectrum of knowledge and skills required for technicians to be able to work safely on and around natural gas vehicles. For more information about training and certification related to this subject, click here. |